In partnership with KANTHAL Heating Technology, we provide our customer with state-of-art and newest technology development in Electrical Heating System solution. Over 85 years history we have accumulated knowledge and experience in the world of electrical heating. We are the leader and the best in the industry; if you are looking for ways to improve your productivity, optimize the quality of your product, or to reduce your energy usage, we are the right partner for you.

Find out more about KANTHAL at www.kanthal.com

KANTHAL electric heating systems selection is the widest on the market. Our heating systems outperform competitor in all temperature ranges, from 50 to 1850 degree Celsius. In addition to the list of our main products, we also supply all required parts and accessories for your heating systems, such as heater ceramic parts, control panel for heater, special insulation material, and all related thermal parts for furnace requirements.

Resistance Heating Elements for High Temperature Heating Application

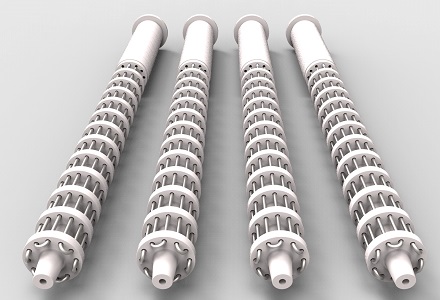

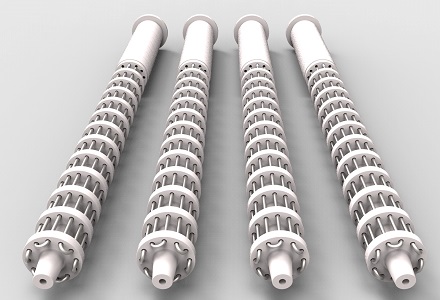

/product-subcategory/heating-wire-strip-and-elementSilicon Carbide (SiC), ceramic heating material up to 1650 Celsius. Branded as KANTHAL Globar Globally.

/product-subcategory/silicon-carbide-sic

Radiant tube is provided for heater protection when heating under demanding furnace atmosphere

/product-subcategory/radiant-tube-heater-bundle-rod-heater

Special Heater and Heater Tube package to be immersed to molten aluminum

/product-subcategory/aluminum-immersion-heater

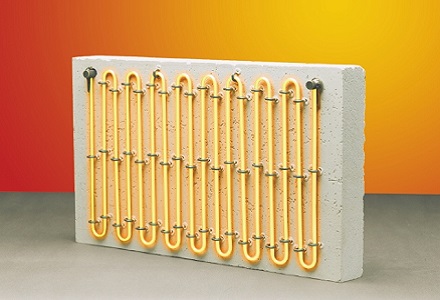

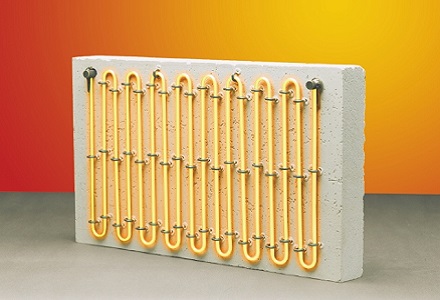

Prefabricated heating modules with metallic heating elements and vacuum-formed ceramic fiber insulation for up to 1350°C element temperature

/product-subcategory/fibrothal-heating-modules

Tubular Heater, Cartridge Heater, Air Heater, Silicon Heater, all heater needed for factory processes

/product-subcategory/industrial-process-heater

Kanthal Super Molybdenum disilicide (MoSi2) heating elements were introduced in 1956, this represented a step upwards on the temperature scale for resistance elements.

/product-subcategory/mosi2-kanthal-super

Furnace and oven up to 1800 Celsius for Laboratory, Foundry, and Heat Treatment process

/product-subcategory/laboratory-furnace-and-ovenResistance Heating Elements for High Temperature Heating Application

Silicon Carbide (SiC), ceramic heating material up to 1650 Celsius. Branded as KANTHAL Globar Globally.

Radiant tube is provided for heater protection when heating under demanding furnace atmosphere

Special Heater and Heater Tube package to be immersed to molten aluminum

Prefabricated heating modules with metallic heating elements and vacuum-formed ceramic fiber insulation for up to 1350°C element temperature

Tubular Heater, Cartridge Heater, Air Heater, Silicon Heater, all heater needed for factory processes

Kanthal Super Molybdenum disilicide (MoSi2) heating elements were introduced in 1956, this represented a step upwards on the temperature scale for resistance elements.

Furnace and oven up to 1800 Celsius for Laboratory, Foundry, and Heat Treatment process